Inventory management has always been at the heart of success in the portable storage industry. From keeping track of containers and trailers to ensuring the right assets are in the right place at the right time, operators know that efficiency and visibility can make or break a business. But it is changing fast, and tools and processes that worked five years ago are becoming obsolete.

As a company that has spent years working alongside portable storage leaders, I believe we’re at a turning point.

The next generation of inventory management isn’t just about tracking assets, it’s about anticipating needs, maximizing utilization, and creating a seamless customer experience from quote to final invoice (and repeat business).

From Reactive to Proactive Operations

Traditionally, inventory management has been reactive – wait for issues to arise before addressing them.

In the future, successful businesses will rely on real-time data and predictive insights to act before problems happen. Knowing exactly when a unit will be returned, which assets are due for maintenance, or where bottlenecks will occur weeks in advance.

This shift requires moving away from spreadsheets and manual tracking. It means integrating systems that connect dispatch, billing, maintenance, and customer communication into a single view, empowering teams to operate faster and smarter.

The Rise of Data-Driven Decision Making

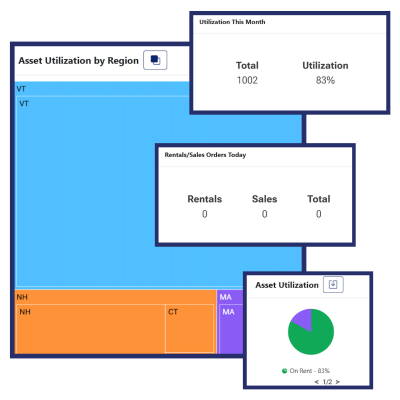

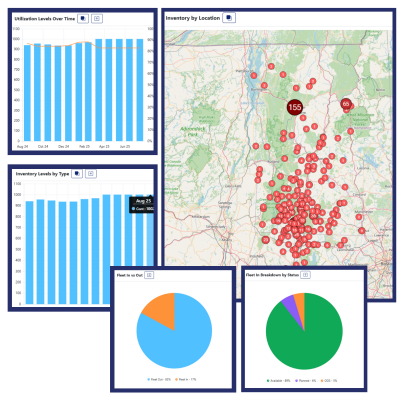

Portable storage companies have always managed physical assets, but the future will demand just as much focus on data as on equipment.

Usage patterns, seasonal demand, regional growth trends – these insights help guide decisions on where to position inventory, when to expand fleets, and how to price competitively.

Operators who harness their data effectively will outpace those who simply react to the market. The ability to see and act on this information in real-time will become a key competitive advantage.

Seamless Communication Across the Operation

Inventory isn’t managed in isolation. It’s tied to sales, customer service, and operations.

The future demands systems that unify communication across every touchpoint.

When sales knows what’s available, dispatch knows where to send it, and customers get timely updates without extra phone calls – everyone wins.

The portable storage companies that thrive will be the ones who eliminate silos and ensure every team member, from the front office to the field, is working from the same, accurate information.

Sustainability and Smart Utilization

We’re also seeing a push toward more sustainable practices in logistics and storage.

Optimizing delivery routes, reducing idle inventory, and extending the life of assets through better maintenance tracking are not just cost-saving measures, they’re competitive differentiators in an increasingly eco-conscious marketplace.

Smart inventory management will be a cornerstone of these efforts, enabling companies to do more with less while meeting customer expectations for fast, reliable service.

A Leadership Responsibility

The future of inventory management is already here. The question is, are you ready to lead it?

Portable storage companies that will thrive in the coming years are those willing to adapt quickly, embrace emerging technologies, and rethink old processes.

It’s no longer enough to simply keep track of what you own. Leaders must focus on how inventory is positioned, how efficiently it’s used, and how seamlessly teams can act on that information.

By combining strategic foresight with operational agility, industry leaders can transform inventory management from a back-office function into a core driver of growth, customer satisfaction, and competitive edge.

The next era of portable storage will be defined not by those who have the most assets, but by those who manage them with the most intelligence, precision, and vision.